In November, it was time to begin preparing machines for storage in the winter period. When you commute, you are the AID Research Center Director, who makes an endless call to Symon & Garfuncule.

This time, I would like to consider the forever theme of machinery work “pressure.”

What do you tread on?

When performing mechanical work, the phenomenon in which the soil of the field is stepped on with a tire such as a attractor, and the soil of the tire trail in particular is tightened is called “Soil Compaction”.

The main reason for the big problem is that the water draining (draining) becomes worse due to tight soil, and the roots of crops become difficult to stretch, eventually reducing crops.

What is happening under the tire?

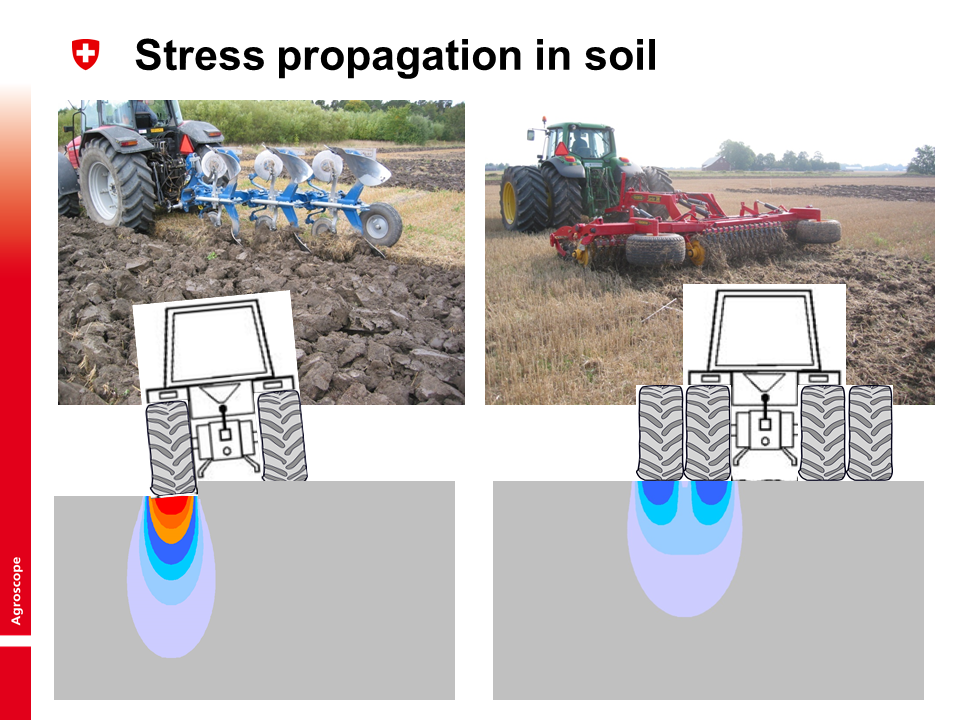

Diagrams of Keller et al.’s dataAccording to the above, the pressure propagates in a ball-like fashion to the soil stepped on by the tire, and the soil is tightened. The red area in the figure is under pressure, and the lighter the blue area is, the less pressure is.

In additionMichelin’s documentationAs indicated, soil stepped on on the tires is compressed and deformed. Especially when touching the tire, it is deformed by a large amount and is tight without gaps.

This will block the water or air path, which can lead to crop roots in environments where it is difficult to grow.

Possible countermeasures against treading

When considering step pressure measures, the keywords are “ground pressure” and “number of runs”.

1. Grounding pressure

Grounding Pressure indicates the pressure on the surface where the tire is against the ground.

Grounding pressure (kg/cm2) = weight of tire (kg)/Grounding area (cm2)

This value is calculated by the formula, and the effect on the tread pressure becomes large.

There are two ways to reduce the grounding pressure from this formula: “Increase the grounding area” or “decrease the weight on the tires”.

(1) Increase the grounding area

・ Crawler

Worldwide growing technology, using a crawler instead of the attractor tires as shown in the picture above. The term crawler refers to the so-called catapilla, which is used in brute-force civil engineering works. It is a registered trademark of Catapilla Co., Ltd. in the U.S.A. and we will use the term crawler this time.

The crawler can touch the soil in a band, thus increasing the grounding area.

・ Double tire

In Mr. Keller’s documentation, as shown on the right, we can see that, with the idea of increasing the grounding area by having the tires in two rows, as shown in the diagram on the right, there are no more red pressure intensive parts and the grounding pressure is reduced.

・ Low-voltage tires

In the Michelin documentation above, the type that expands the grounding area when the air pressure of the tire is low, such as the type on the right side, is called the “low-pressure tire”. This tire increases the grounding area and reduces the amount of soil deformation, as shown in this figure.

(2) Reduce the weight on the tire

Next, the idea is to lighten the weight on the tires, but there is an important point. This means that the attractor must balance the force of attracting the machine, the so-called “attraction”.

In general, the gravity increases proportionally to the weight of the tire. (If you have experienced running a heavy load on the rear seat when driving winter roads with a rear-wheel drive, you may be able to understand the image.)

For this reason, if “attraction” is necessary in the work of waking up the field etc., it may be preferable to use a attractor whose “weight on the tire” is heavy, i.e., the body weight is large.

On the other hand, for operations that do not require much “gravity”, such as grass removal, it is desirable to select a attractor with a light “weight on the tire” and a small airplane weight.

In reality, when “attraction” is required, it is necessary to use the attractor with large airplane weight. In such a case, it is necessary to use a double tire or a low-pressure tire to increase the “grounding area” so as not to raise the “grounding pressure”.

2. Number of runs

The number of times the tire steps on the same place, the so-called “number of trips” also affects stepping down.

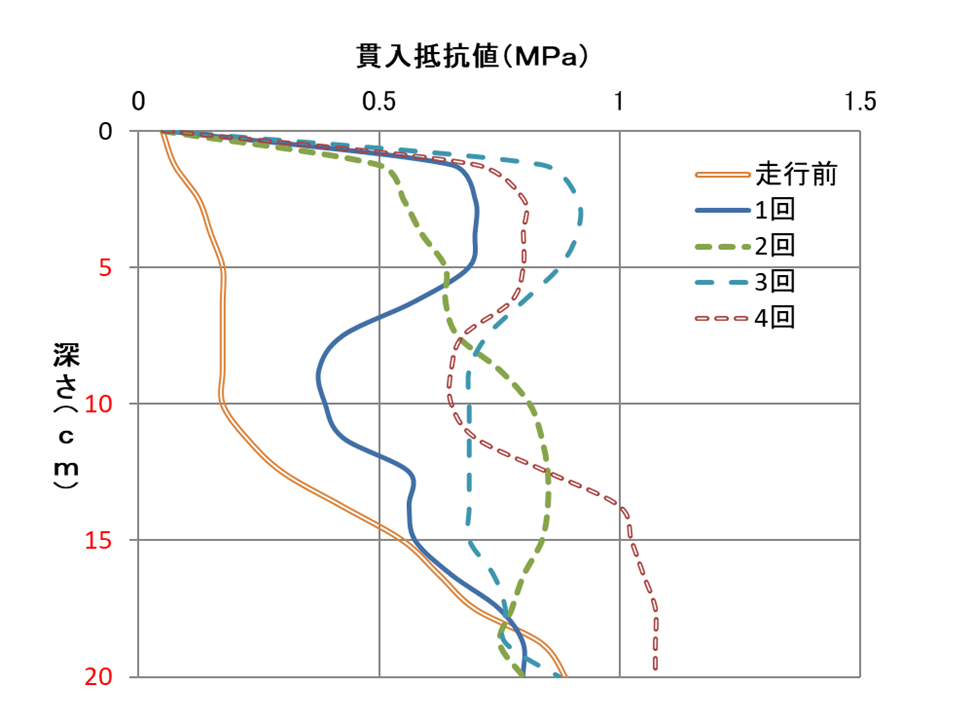

The figure compares the intrusion resistance values (indicating soil hardness) by depth at different travel times. In this figure, especially when the number of runs is 2 or more at a depth of 10 to 15cm, the intrusion resistance value shows a higher value than before and once, and the soil becomes very hard.

As a result, it can be seen that the influence of step pressure increases in the work method of running the same part twice or more.

To reduce the number of runs, for example, when performing a seeding operation, you can use a hello to perform a crushing operation in the front part of the attractor, and a “multi-function machine” to attach a seeding machine in the back part.

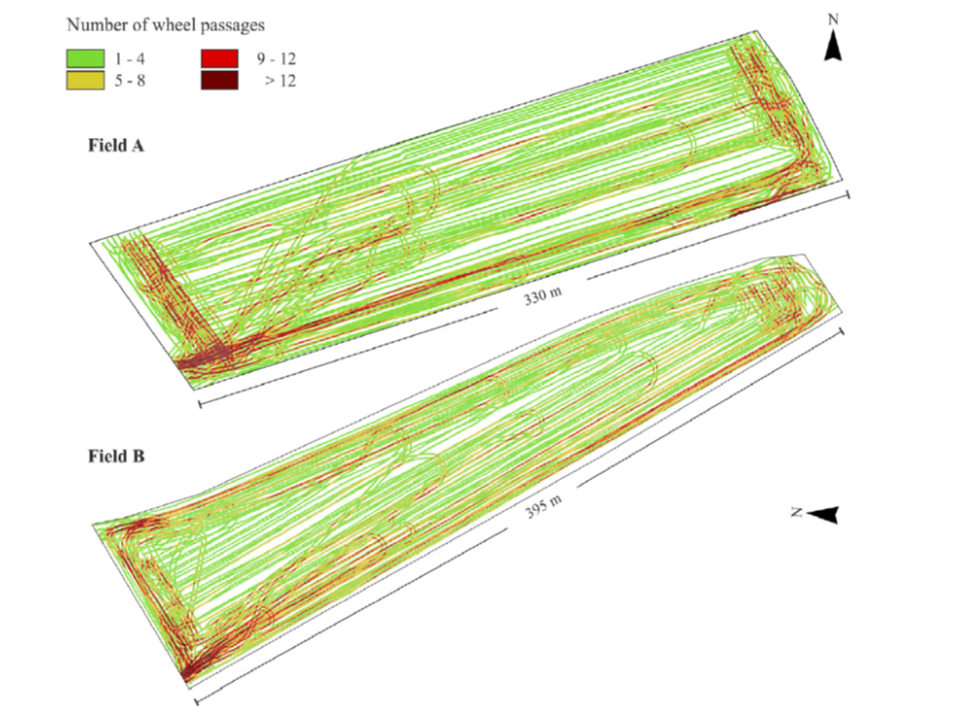

And more recentlyDuttmann et al. papersAs you can see, more and more attempts have been made to create a map of travel times from GPS-based travel trajectory data.

When such a map is used, for example, it can be used in combination with a “growing map” of crops using sky-shot data or a “yield map” obtained from a yield sensor attached to a combination, etc., to infer that the soil environment will deteriorate due to stepping down on the cause of growing defects or declining yield.

This time, I considered “step pressure”, which is a big problem in the machine work, but I think that the “map of the number of runs” shown last is an item that I would like to add to our products in the future, but I will do it…