I am the director of the AID Research Center, and I was recently impressed by the soft-serve ice cream served on a plate at Komeda Coffee Shop.

In this issue, we will explore trends in the development of agricultural machinery utilizing ISOBUS based on the latest information.

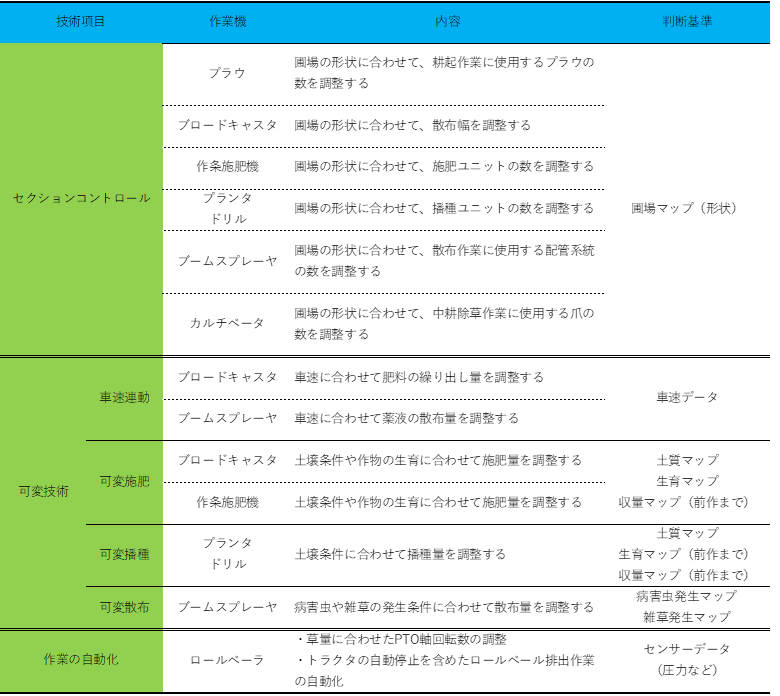

I’ll try to categorize the technical items…

The technologies that utilize ISOBUS can be broadly divided into

Section Control

Variable technology

Automation of operations

The three categories are

Among these, “section control” and “variable technology” are technologies that are actually being introduced in paddy and field crops, but the criteria for judgment are based on the use of “maps” that organize various types of information.

On the other hand, “automation of work” requires the introduction of a control method called “sequence control,” in which control is performed in accordance with a predetermined sequence, and “sensor data” is used as the basis for control decisions. Currently, the roll baler used in feed production is the most advanced in terms of development, and practical machines are on the market.

section control

Section control has been introduced before with examples of broadcasters and seeders, and Kuhn has developed a plow that is compatible with section control.

Variable technology

The most widespread variable technology is variable fertilizer application, which combines a growth map generated from satellite imagery with a broadcaster.

Amazone, on the other hand, is developing a boom sprayer that uses drone imagery to generate a map of weed locations and then uses that map to perform “variable spraying” of herbicides.

Work Automation

Automation of work is the most promising technology for the development of work equipment utilizing ISOBUS, as we have previously discussed in an article on ISOBUS- TIM.

Kubota is also developing a roll baler that utilizes ISOBUS-TIM.

Future Issues

Future issues to be addressed

1. Technology utilizing ISOBUS at the present stage focuses on “Map Pace” technology, and new “Map” generation technology linked with Geographic Information System (GIS) methods is required to be developed in conjunction with machine development.

2. “Sequence control flow” and “sensor technology” technology development tailored to the work is necessary to promote “work automation”.

The two points are as follows.